When it comes to laser systems, particularly in the fields of engraving, cutting, and marking, two prominent types often come into discussion: the Plotter Table Style Laser and the Galvanometer (Galvo) Laser. Both have unique characteristics, advantages, and applications. In this blog, we’ll dive deep into understanding these differences, helping you decide which might be the best fit for your needs.

Table XY Plotter Laser: Precision and Versatility

What is a Plotter Table Style Laser?

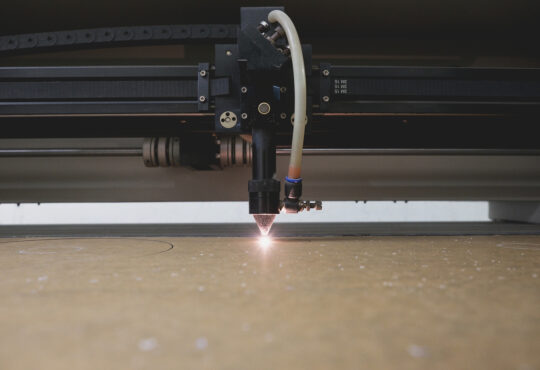

A Plotter Table Style Laser, often referred to simply as a plotter laser, operates much like a traditional printer. It uses a laser mounted on an X-Y mechanical system, moving over a stationary workpiece (usually placed on a flat table) to engrave or cut the material.

Key Features:

- Large Working Area: These lasers typically have a larger working area, making them suitable for bigger projects.

- Precision: They offer high precision over the entire working area.

- Versatility: Plotter lasers can work with a variety of materials, including wood, acrylic, and metal.

- Speed: While generally slower than galvo lasers, they provide consistent quality over larger areas.

Ideal Applications:

- Large scale engraving projects.

- Detailed cutting of materials like wood or acrylic.

- Applications where material size and thickness vary.

Galvanometer (Galvo) Laser: Speed and Efficiency

What is a Galvo Laser?

Galvo lasers use mirrors mounted on galvanometers (hence the name) to rapidly deflect the laser beam across the work surface. This setup allows for extremely fast marking and engraving, especially over smaller areas.

Key Features:

- High Speed: Galvo systems can move the laser beam very quickly, making them ideal for high-speed marking.

- Smaller Footprint: These systems are typically more compact due to the stationary laser and moving mirrors.

- Focused on Small Areas: They are best suited for smaller work areas, though field lenses can expand the area to some extent.

- Less Versatile with Materials: While versatile, they may not handle thicker materials as effectively as plotter lasers.

Ideal Applications:

- High-speed marking of metals and plastics.

- Serial number engraving.

- Small-scale, detailed artwork or text.

Comparing the Two

Speed and Efficiency

- Plotter Laser: Better for larger and more complex jobs, but slower.

- Galvo Laser: High-speed operation, best for repetitive, small-scale jobs.

Precision and Quality

- Plotter Laser: Offers consistent precision across a large area.

- Galvo Laser: Extremely precise but over a smaller area.

Flexibility and Material Handling

- Plotter Laser: More flexible in terms of material type and thickness.

- Galvo Laser: Best for thinner materials and high-speed operations.

Cost and Size

- Plotter Laser: Generally larger and potentially more expensive due to size.

- Galvo Laser: More compact and may be less expensive, especially for smaller models.

Conclusion

In summary, your choice between a Plotter Table Style Laser and a Galvo Laser should be guided by the specific requirements of your projects. If you need to work on large pieces with varied materials, a Plotter Laser is your go-to. However, if your focus is on high-speed, small-scale engraving and marking, a Galvo Laser will serve you better.

Remember, the right tool not only enhances efficiency but also opens up new possibilities in your creative or industrial endeavors. Happy lasering!