In the world of manufacturing and fabrication, precision, creativity, and efficiency are paramount. Companies that specialize in working with plastic and acrylic materials face unique challenges in meeting these demands. However, in recent years, laser engraving and cutting technology have emerged as true game changers for plastic and acrylic fabricators. These advanced tools offer a plethora of advantages that not only streamline production but also unlock new possibilities for design and customization. In this blog post, we will delve into why laser engraving and cutting have become indispensable for plastic and acrylic fabricators.

The Evolution of Laser Technology

To appreciate the profound impact of laser engraving and cutting on plastic and acrylic fabrication, it’s crucial to understand the evolution of laser technology. Lasers, short for “Light Amplification by Stimulated Emission of Radiation,” were developed in the 1960s and have undergone continuous refinement since then.

Today’s laser cutting and engraving systems are the result of decades of innovation and development. These systems utilize high-powered laser beams to precisely cut, engrave, and mark materials without physical contact, making them an ideal tool for the intricate work required in plastic and acrylic fabrication.

Precision and Accuracy

One of the most significant advantages that laser engraving and cutting offer to plastic and acrylic fabricators is their unmatched precision and accuracy. Traditional cutting methods, such as sawing or milling, often result in rough edges, burrs, and inconsistent shapes. Laser systems, on the other hand, provide pinpoint precision and produce clean, smooth cuts without any material deformation.

This level of precision is invaluable for plastic and acrylic fabricators who deal with intricate designs, tight tolerances, and delicate materials. Whether it’s crafting intricate components, prototyping, or creating intricate artistic displays, laser technology ensures that each piece meets the desired specifications with utmost accuracy.

Versatility in Materials

Plastic and acrylic fabricators work with a wide range of materials, each with its own set of characteristics and challenges. Laser engraving and cutting systems excel in their versatility, as they can work with an extensive selection of plastics and acrylics, including:

- Cast Acrylic

- Extruded Acrylic

- Polycarbonate

- Delrin

- PET

- PETG

- Polypropylene

- Polyethylene

- Styrene

This versatility allows plastic and acrylic fabricators to diversify their product offerings, cater to various industries, and explore new design possibilities. Whether it’s crafting signage, packaging, promotional materials, or customized components, laser systems can tackle the job with ease.

Speed and Efficiency

Time is of the essence in manufacturing, and laser engraving and cutting systems are renowned for their speed and efficiency. These machines can process materials much faster than traditional cutting methods, allowing plastic and acrylic fabricators to increase their production capacity while maintaining consistent quality.

Moreover, laser systems typically require minimal setup time, reducing downtime between jobs. This enhanced efficiency not only saves time but also reduces operational costs, making it a cost-effective solution for fabricators.

Reduced Waste

Traditional cutting methods generate a significant amount of waste material in the form of shavings, dust, and off-cuts. Laser engraving and cutting systems, in contrast, minimize waste production. The laser beam is so precise that it can cut intricate shapes with minimal kerf (the width of the cut), resulting in less material wastage.

Reduced waste not only contributes to cost savings but also aligns with environmental sustainability goals. Plastic and acrylic fabricators can reduce their ecological footprint by adopting laser technology as a cleaner and more efficient cutting method.

Intricate Designs and Personalization

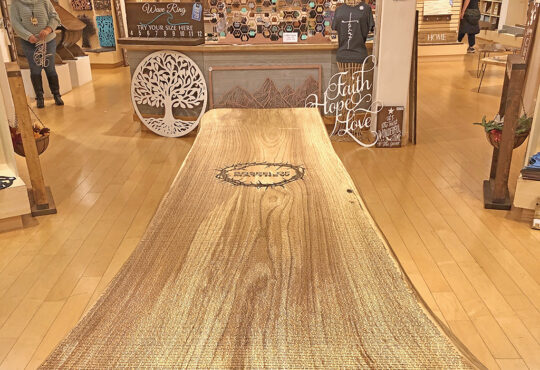

Laser engraving and cutting systems empower plastic and acrylic fabricators to push the boundaries of creativity. These machines can produce intricate designs, detailed engravings, and complex shapes that were previously challenging or impossible to achieve using traditional methods.

Additionally, laser technology allows for personalization on a level that was once unimaginable. Fabricators can offer custom-made products, adding names, logos, and unique designs to their offerings. This personal touch can significantly enhance customer engagement and brand loyalty.

Minimal Maintenance

Maintenance is a critical aspect of any machinery, and laser engraving and cutting systems are known for their reliability and minimal upkeep requirements. These machines have fewer moving parts compared to traditional cutting equipment, resulting in fewer components that can wear out or break down.

Routine maintenance typically involves tasks like cleaning the lens, checking alignment, and ensuring proper ventilation. With proper care, laser systems can operate smoothly for an extended period, reducing downtime and maintenance costs for fabricators.

Improved Safety

Safety is a top priority in any manufacturing environment. Laser engraving and cutting systems are designed with safety in mind. They often feature enclosed workspaces, interlock systems, and exhaust systems to remove fumes and debris.

These safety measures protect both operators and the integrity of the products being manufactured. Compared to some traditional cutting methods that involve sharp blades or rotating machinery, laser systems are a safer option for workers.

Automation and Integration

In an era characterized by Industry 4.0, automation and integration are key drivers of efficiency and competitiveness. Laser engraving and cutting systems can be seamlessly integrated into existing production processes, allowing for automation and streamlining of workflows.

Automation reduces the need for manual labor, lowers the risk of errors, and increases overall productivity. Plastic and acrylic fabricators can connect their laser systems to computer-aided design (CAD) software, enabling precise control and customization of manufacturing processes.

Cost-Effectiveness

While the initial investment in laser engraving and cutting systems may appear substantial, the long-term cost-effectiveness is undeniable. The combination of reduced waste, increased efficiency, minimal maintenance, and improved material utilization ultimately results in significant cost savings over time.

Furthermore, the versatility of laser technology enables plastic and acrylic fabricators to expand their product offerings, potentially tapping into new markets and revenue streams. The ability to handle a variety of projects with a single machine makes laser systems a wise financial choice for businesses.

Conclusion

In conclusion, laser engraving and cutting have emerged as game changers for plastic and acrylic fabricators, offering a myriad of advantages that enhance precision, versatility, efficiency, and creativity. These technologies enable fabricators to produce high-quality products, reduce waste, and operate with increased cost-effectiveness.

As the manufacturing industry continues to evolve, it is evident that laser technology will play a pivotal role in the success and growth of plastic and acrylic fabricators. By embracing these innovative tools, businesses can stay ahead of the competition, meet customer demands for customization, and contribute to a more sustainable and efficient future.

In an era where precision and flexibility are paramount, laser engraving and cutting are undoubtedly indispensable tools for any plastic and acrylic fabricator striving to excel in the modern marketplace.