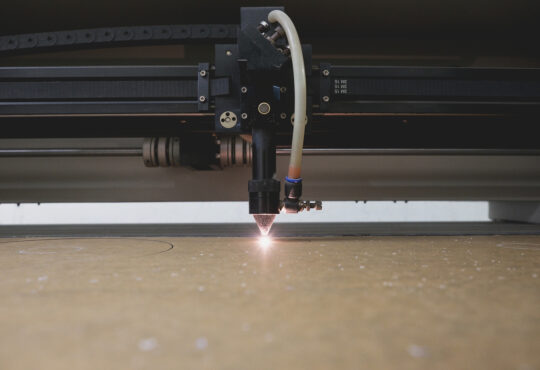

In the realm of laser technology, CO2 and fiber lasers stand out as two of the most prominent types, each with its unique capabilities and applications. While both are essential tools in modern manufacturing and material processing, understanding their differences is crucial for making informed decisions. This blog post dives into the key distinctions between CO2 and fiber laser systems, shedding light on their mechanics, efficiency, material compatibility, and more.

Basic Technology and Mechanics

CO2 Lasers: CO2 lasers operate using a gas mixture predominantly composed of carbon dioxide, stimulated electrically to produce light. The laser beam is generated in a gas-filled chamber and reflected through a series of mirrors to focus on the material. This technology has been a staple in the industry for decades, known for its reliability and effectiveness in a wide range of applications.

Fiber Lasers: In contrast, fiber lasers utilize a core made from optical fibers doped with rare-earth elements like Ytterbium. These fibers are stimulated by diodes, and the laser light is channeled and amplified within the fiber core itself. This modern approach to laser design offers enhanced beam quality and energy efficiency.

Wavelength and Material Interaction

CO2 Lasers: With a longer wavelength of 10.6 micrometers, CO2 lasers are particularly adept at cutting non-metallic materials such as wood, acrylic, glass, and plastics. They can also process metals, but with certain limitations in thickness and type.

Fiber Lasers: Fiber lasers emit a shorter wavelength of around 1.06 micrometers, which is more readily absorbed by metals. This makes them ideal for processing a wide array of metals including steel, aluminum, and copper with high efficiency and precision.

Efficiency and Power Consumption

CO2 lasers, while powerful, are generally less energy-efficient compared to fiber lasers. The energy conversion in CO2 lasers is lower, leading to higher power consumption for the same output. Fiber lasers, with their streamlined design and minimal moving parts, boast higher energy efficiency, translating to lower operational costs and a smaller carbon footprint.

Speed and Precision

When it comes to cutting speed and precision, fiber lasers often have the upper hand. Their focused and intense beam allows for faster cutting speeds, particularly in thin to medium-thickness materials. The precision offered by fiber lasers is unparalleled, making them the preferred choice in industries where fine, detailed work is required.

Maintenance and Lifespan

Maintenance is another area where fiber lasers excel. CO2 lasers, with their complex setup involving mirrors and gas circulation, require more maintenance and calibration. Fiber lasers, on the other hand, have fewer moving parts and a solid-state setup, resulting in lower maintenance needs and longer lifespans. This reliability makes them a cost-effective solution over time.

Cost and Return on Investment

The initial investment in fiber laser technology can be higher than CO2 lasers. However, considering the lower operational and maintenance costs, along with higher efficiency, the return on investment with fiber lasers can be more favorable in the long run. The choice depends on the specific application, material types, and scale of operations.

Conclusion

Both CO2 and fiber lasers have their place in the world of material processing and manufacturing. The choice between the two depends on a variety of factors including material type, desired precision, efficiency, and cost. Understanding these differences is key to selecting the right laser system for your specific needs, ensuring optimal performance and cost-effectiveness in your operations. Whether you’re cutting intricate designs in metal or engraving on non-metallic surfaces, there’s a laser system tailored to your requirements.