Choosing the right laser engraver for your business is a decision that can significantly impact your operations, efficiency, and profitability. To make an informed choice, it’s important to consider several key factors. Here’s an expanded look at the four crucial considerations:

1. Type of Material to be Engraved

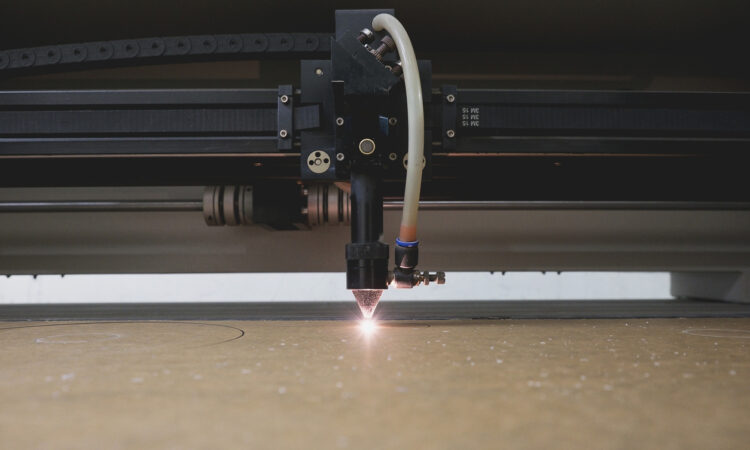

The first step is to identify the primary materials your business will work with, as this will dictate the type of laser engraver you need.

- CO2 Lasers: These are the most versatile and commonly used for materials such as wood, acrylic, glass, leather, fabric, and certain plastics. They are not suited for engraving metals, however.

- Fiber Lasers: Ideal for engraving metals and some types of plastics. They are more expensive but essential for businesses focusing on metalwork.

- Crystal Lasers: These can work with both metals and plastics but are less common due to their higher costs and shorter lifespan compared to fiber lasers.

2. Engraving Size and Power

The size of the engraving area and the laser’s power are key factors that will affect your work’s efficiency and quality.

- Engraving Area: A larger area provides more flexibility for different-sized projects but will increase the machine’s footprint and cost. Consider the maximum size of the items you plan to engrave regularly.

- Laser Power: Higher wattage lasers can engrave faster and deeper but consume more power and have higher upfront costs. A balance must be struck between efficiency, quality, and cost.

3. Software Compatibility and Ease of Use

The software that controls the laser engraver is as important as the machine itself.

- Ease of Use: User-friendly software with a gentle learning curve is vital, especially for businesses new to laser engraving.

- Compatibility: Ensure the software is compatible with your existing systems and can handle various file types.

- Advanced Features: Look for software with features like 3D engraving capabilities, detailed image tracing, and customization options to provide more value to your clients.

4. Cost, Maintenance, and Return on Investment

Balancing the initial cost, ongoing maintenance, and potential ROI is crucial for making a cost-effective decision.

- Initial Investment: This includes not only the cost of the machine but also installation, training, and any additional equipment needed.

- Maintenance and Operating Costs: Regular maintenance is crucial for longevity and consistent performance. Factor in the costs of replacement parts, materials, and energy consumption.

- ROI Considerations: Assess how the laser engraver will contribute to your business. Will it open up new markets? Improve production efficiency? Ensure that the benefits justify the costs.

Additional Considerations

- Safety and Ventilation: Laser engraving can produce fumes and require safety measures. Ensure your workspace is equipped with proper ventilation and safety equipment.

- After-Sales Support: Consider the level of customer service and technical support offered by the manufacturer. Good after-sales support can be invaluable for troubleshooting and maintenance.

- Community and Reviews: Research user reviews and seek advice from the community of laser engraver users. Their insights can be helpful in understanding the real-world performance and reliability of the machines.

Conclusion

Selecting a laser engraver is a multifaceted decision that should be approached with thorough research and consideration. Assess your business’s specific needs, the types of materials you’ll be working with, the size and power requirements of your projects, the software’s compatibility and ease of use, and the overall cost and potential ROI. By carefully evaluating these factors, you can choose a laser engraver that not only meets your current needs but also supports your business’s growth and success in the long term.