In the dynamic world of manufacturing, laser cutters have emerged as a game-changer, especially for companies specializing in the creation of nameplates, tags, and metal labels. This advanced technology has revolutionized the way these items are produced, offering unparalleled precision, efficiency, and versatility. In this blog, we delve into the reasons why laser cutters are an indispensable tool for such companies, with a special focus on the accuracy afforded by vision systems in cutting preprinted materials.

Unmatched Precision and Quality

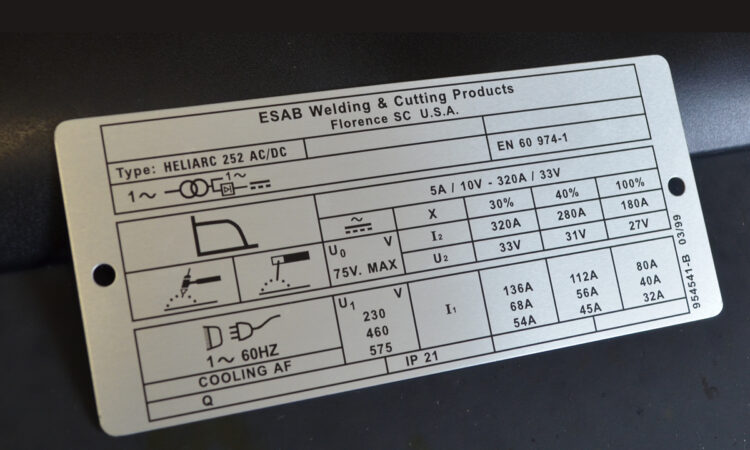

Intricate Detailing: Laser cutters are renowned for their ability to produce extremely detailed cuts and engravings. For nameplates, tags, and labels, which often feature fine text and intricate logos, the precision of a laser cutter is invaluable.

Consistent Quality: In mass production, consistency is key. Laser cutters ensure that each piece is a perfect replica of the last, guaranteeing uniform quality across all products.

Efficiency and Speed

Rapid Production Rates: Speed is a significant advantage of laser cutting technology. These machines can operate at high speeds, significantly reducing production time compared to traditional methods, which is crucial for meeting tight deadlines and high-volume demands.

Automation and Reduced Labor Costs: The automation capabilities of laser cutters minimize manual intervention, streamlining the production process, reducing labor costs, and diminishing the likelihood of human error.

Versatility in Materials

Broad Material Compatibility: Laser cutters can work with a diverse range of materials, including various metals, plastics, and composites, making them ideal for companies that produce a wide array of nameplates, tags, and labels.

Minimal Material Damage: The non-contact nature of laser cutting means there’s less risk of material distortion or damage, preserving the integrity of delicate materials.

Customization and Adaptability

Easy Design Modifications: Laser cutters allow for effortless customization. Designs can be quickly altered and adapted without the need for new physical tools, offering great flexibility to cater to client-specific requirements.

On-Demand Production: With laser cutting, companies can produce exactly what they need, when they need it, leading to efficient inventory management and reduced waste.

Enhanced Accuracy with Vision Systems

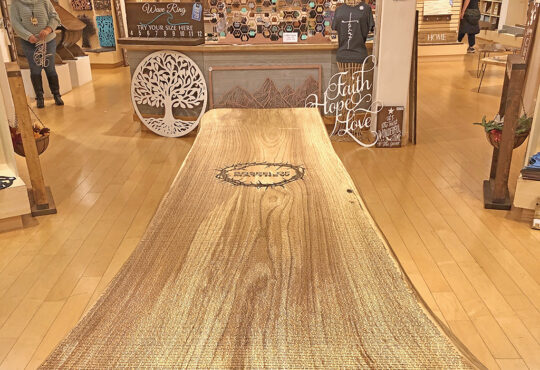

Cutting Preprinted Materials: One of the standout features of modern laser cutters is the integration of vision systems. These systems enable the cutter to accurately cut preprinted materials. The vision system can recognize and align with printed graphics, ensuring precise cuts that match the printed design perfectly.

Reduced Errors and Waste: The accuracy provided by vision systems significantly reduces errors, resulting in less material waste and higher quality products. This is particularly crucial when working with expensive materials.

Durability and Longevity

Long-Lasting Products: Laser-engraved tags and labels are known for their durability. The markings are resistant to fading, wear, and environmental conditions, ensuring that information remains legible over time.

Environmental Considerations

Reduced Waste: The precision of laser cutting results in minimal material wastage. This not only makes the process cost-effective but also more environmentally friendly.

Conclusion

For companies in the business of producing nameplates, tags, and metal labels, laser cutters represent a significant investment in quality, efficiency, and versatility. The integration of vision systems for cutting preprinted materials further enhances their capability, ensuring accuracy and reducing waste. As technology continues to advance, laser cutters are set to become even more indispensable in these industries, driving innovation and excellence in manufacturing practices.