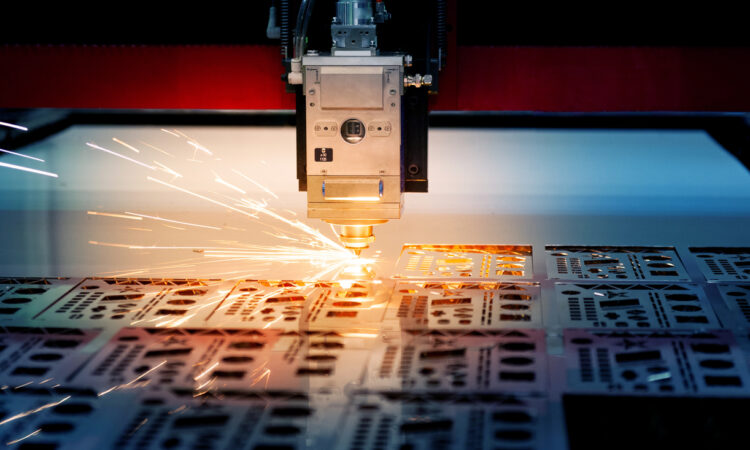

In recent years, there’s been a notable surge in the adoption of laser cutting technology across various industries. This growth can be attributed to the unparalleled precision, efficiency, and versatility that laser cutters offer. From automotive manufacturing to fine arts, laser cutting is revolutionizing how businesses approach design and production.

1. Technological Advancements in Laser Cutting

The evolution of laser technology has been a key driver in its increased industrial use. Modern laser cutters are more precise, faster, and energy-efficient than their predecessors. The introduction of fiber lasers has been particularly transformative, offering enhanced cutting speeds and capabilities for processing a wide range of materials, including metals, plastics, and composites.

2. Increased Demand for Precision and Efficiency

In industries where precision is paramount, such as aerospace and medical device manufacturing, laser cutters have become essential. They provide unmatched accuracy in cutting intricate designs and complex shapes, which is critical in these high-stakes sectors. Additionally, the speed of laser cutting accelerates production times, enabling industries to meet growing consumer demands more efficiently.

3. Cost-Effectiveness and Sustainability

Despite the initial investment, laser cutters are cost-effective in the long run. They reduce waste through precise cutting, lowering material costs. Moreover, laser cutters consume less energy compared to traditional cutting methods, aligning with the growing emphasis on sustainable manufacturing practices.

4. Versatility Across Industries

The versatility of laser cutters is evident in their wide range of applications. In the automotive industry, they’re used for cutting complex components with high precision. In the fashion and textile industry, laser cutters are employed for detailed fabric cutting and engraving. Even in architecture and design, laser cutting is utilized to create intricate models and components.

5. Customization and Innovation

Laser cutting technology has opened new avenues for customization and innovation. It allows for easy adjustments and rapid prototyping, enabling businesses to experiment with new designs and products without extensive time or financial commitments. This flexibility is a significant advantage in today’s fast-paced market where customization is increasingly valued.

6. Challenges and Future Prospects

Despite its many benefits, the integration of laser cutting technology comes with challenges. The initial cost can be prohibitive for small businesses, and there is a need for skilled operators to manage these sophisticated machines. However, as technology advances and becomes more accessible, these barriers are likely to diminish.

Looking ahead, the future of laser cutting in industry appears bright. With ongoing technological advancements, we can expect laser cutters to become even more efficient, affordable, and integrated into various manufacturing processes. The potential for increased automation and integration with AI and machine learning technologies also holds exciting prospects for further innovation and efficiency in industrial laser cutting.

Conclusion

The rise of laser cutters in industry marks a significant shift towards more precise, efficient, and sustainable manufacturing processes. As this technology continues to evolve and become more accessible, it’s poised to play an increasingly vital role in various sectors, driving innovation and efficiency in manufacturing worldwide.