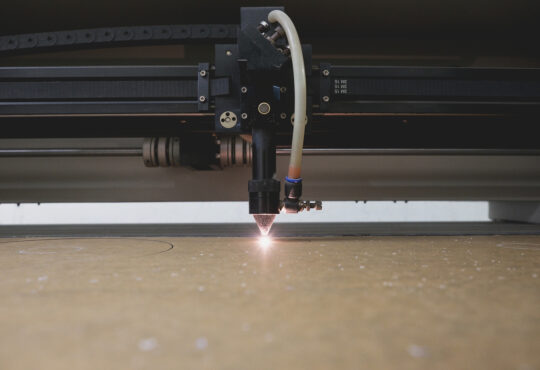

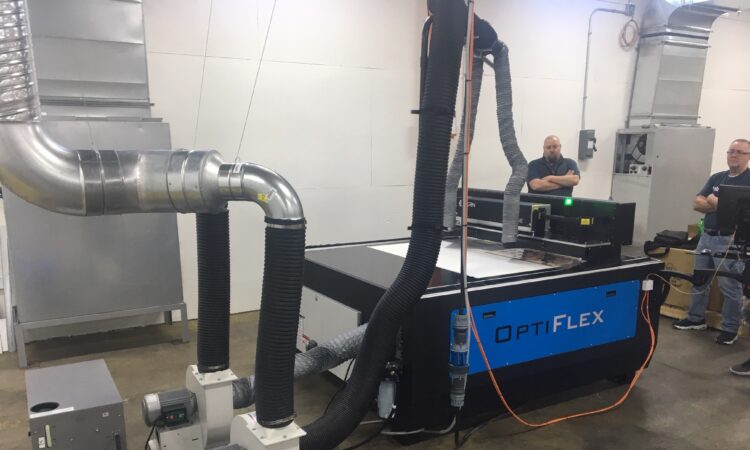

For companies aiming to boost their production capabilities, open format laser systems are becoming an increasingly popular solution. Traditionally, concerns regarding safety have been associated with these systems due to their open and accessible nature. However, recent innovations in safety technology, including the integration of safety mats, light curtains, safety bumpers, and laser safety glasses, have greatly improved their safety profile. This blog post discusses how open format laser systems can effectively increase production while incorporating these advanced safety features to ensure a secure working environment.

Advantages of Open Format Laser Systems in Production

Flexibility in Production: Open format laser systems are highly adaptable, accommodating a wide variety of materials and sizes. This flexibility is crucial for handling large or irregularly shaped items, a challenge often encountered with enclosed systems.

Efficiency in Operations: These systems allow for quick and easy setup and transitions between jobs. The open design facilitates faster material handling and adjustments, leading to increased efficiency in production cycles.

Real-time Process Monitoring: Open format systems offer clear visibility of the operational area, enabling operators to monitor the process closely and make on-the-fly adjustments, a significant advantage for precision-driven tasks.

Incorporating Cutting-Edge Safety Features

Modern open format laser systems have significantly advanced in safety, making them a viable option even in environments with stringent safety requirements:

Light Curtains: Light curtains create an invisible safety barrier around the laser’s working area. When this barrier is breached, the laser system automatically shuts down, preventing accidental exposure to the laser beam.

Safety Bumpers: These physical sensors attached to the moving parts of the laser system act as an immediate stop mechanism upon contact with an object or person, providing an additional layer of safety.

Safety Mats: Safety mats are another innovative addition to the safety arsenal. Placed around the laser system, these mats detect pressure changes caused by someone stepping on them and immediately halt the laser operation, preventing potential accidents.

Laser Safety Glasses: For additional personal protection, operators and employees in the vicinity can wear laser safety glasses. These specialized glasses are designed to protect the eyes from the specific wavelengths of light emitted by the laser, reducing the risk of eye damage.

Adhering to Safety Protocols

Compliance with Safety Standards: With these enhanced safety measures, open format laser systems align with the latest safety standards, ensuring a secure work environment.

Employee Training and Awareness: Effective training programs for operators and staff about the laser system’s features and safety protocols are essential for maximizing safety.

Balancing High Productivity with Safety

Efficiency Meets Safety: The addition of advanced safety features means companies no longer have to compromise between productivity and safety. Open format laser systems now provide a method to enhance production while maintaining a secure workplace.

Customization and Scalability: These systems are also highly adaptable, allowing for modifications and upgrades as production requirements evolve.

Conclusion

Open format laser systems, now equipped with state-of-the-art safety technologies like safety mats, light curtains, safety bumpers, and laser safety glasses, present a robust solution for companies seeking to augment their production capacity. These advancements in safety not only comply with stringent safety regulations but also open doors for higher efficiency and productivity in various industries. Embracing these technologies signifies a forward-thinking approach in manufacturing and design, where high output and safety go hand in hand.